Multi-Tank-Automatic Vacuum Cleaner CH-HMTV Series

Multi-Tank-Automatic Vacuum Cleaner CH-HMTV Series

| Project |

Specification |

|

Use solvent

|

- Hydrocarbon solvents (carbonized hydrogen), modified alcohols, or other non-aqueous organic solvents.

|

|

Cleaning

|

- Process A:vacuum ultrasonic cleaning→atmospheric pressure dip→Steam shower→

Vacuum drying

- Process B:Tmodified hydrocarbon→modified hydrocarbon ultrasonic→vacuum

ultrasonic cleaning→atmospheric pressure dip→Steam shower→Vacuum drying

- ※Process A:Clean lipophilic dirt. Process B:cleaning hydrophilic and lipophilic dirt.

|

|

Cycle time

|

- 6~10min/ basket(Different washing weight, different output time)

|

|

Loss of lotion

|

|

| Recleovering volume |

- >180L/hr (based on hydrocarbon solvents)

|

| Input and output |

- Manual cart/automatic conveying (optional)

|

|

Loading capability

|

|

|

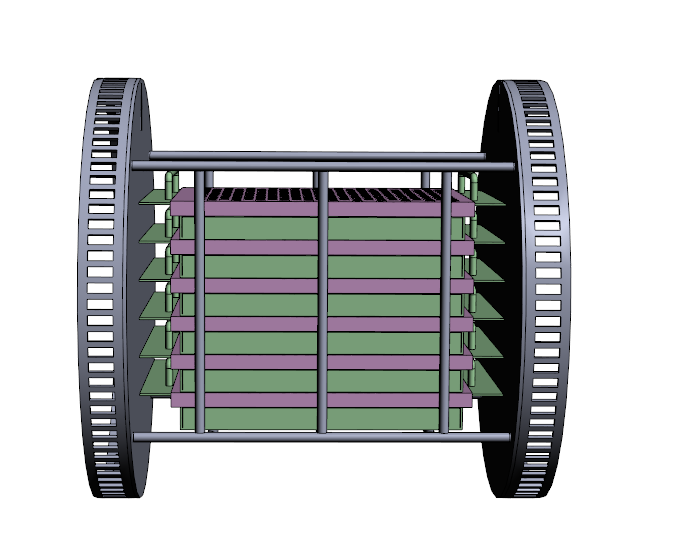

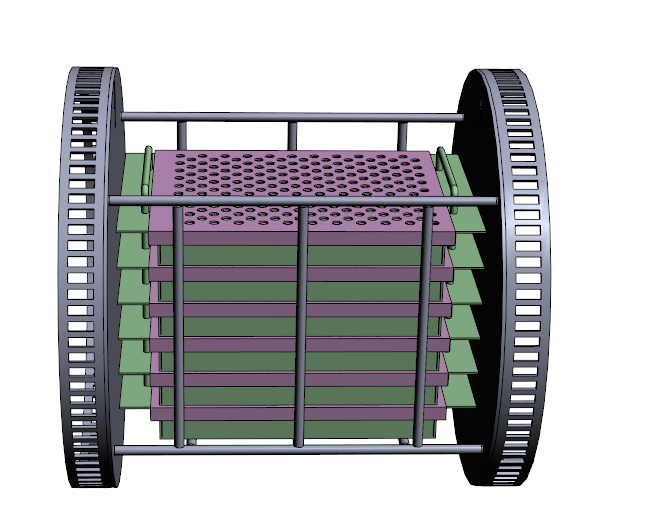

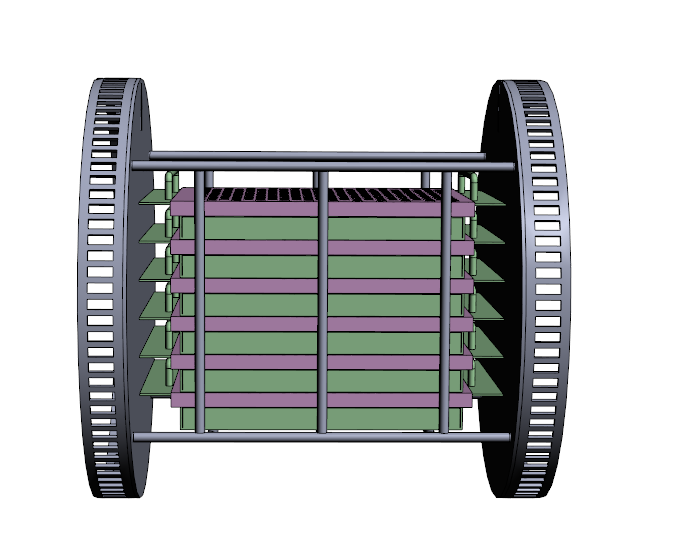

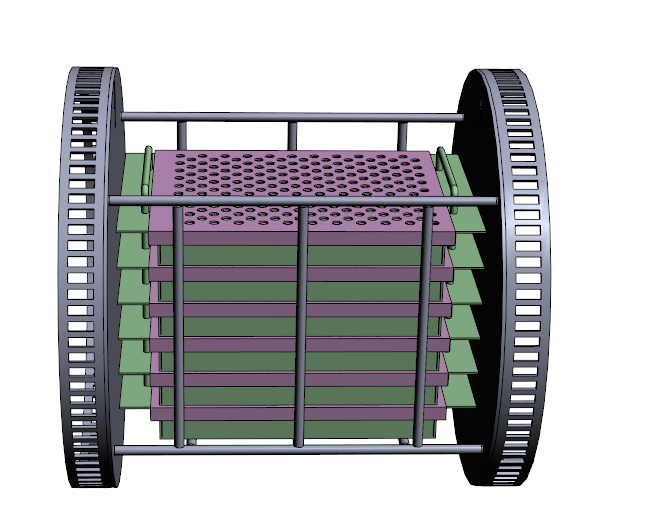

Rotating mechanism

|

- No rotation / rotation / rotation + shaking (optional)

|

|

Equipment Specifications

|

- Customized cleaning equipment.

|

| Characteristic |

- Any hydrophilic or lipophilic processing oil can be cleaned.

- Automatic transmission mechanism, suitable for large-scale production operations.

- Air emissions are much lower than VOC standards, in line with ROHS or any other

environmental protection regulations.

-

Large recovery volume of lotion (≧200L/hr), which makes it easier to maintain the

cleanliness of lotion.

-

The rotating and shaking mechanism of square basket or drum can be used at the same time, which can meet any requirement of workpiece cleaning.

-

Steam cleaning greatly improves the cleanliness of the workpiece, which can meet any severe precision cleaning.

-

100% dry workpiece after vacuum drying.

-

No oxidation occurs after cleaning.

-

No environmental issues such as waste water and air pollution discharge.

|

| Rolling basket schematic |

|